How Chewing Gum is Made? | Chewing Gum Making Process

2022-10-19

How Chewing Gum is Made?

| Chewing Gum Making Process

Chewing gum is a product that has been around for centuries, with the earliest records of people chewing gum dating back to the ancient Greeks. Today, the gum is made using a variety of different ingredients and methods. In this blog post, we'll take a look at how chewing gum is made from start to finish.

💥1. Acceptance of Raw and Auxiliary Materials:

(1) Acceptance of white granulated sugar:

Check whether the outer package is complete, whether there is any phenomenon of damage, moisture and lumping, and the supplier shall provide the testing report of the current batch. If there are any of the above phenomena, it will be returned for processing. Then sample to test the water, if it exceeds the standard, the quality inspection department can be returned depending on the specific situation.

(2) Glucose syrup acceptance:

Check whether the transport tanker is hygienic, if the hygiene does not meet the requirements, then the quality inspection department can make returns according to the specific situation. And sample testing solids content, if does not meet the requirements, then according to the specific situation can be returned.

(3) gum-based raw materials:

Check whether the outer packaging is complete and not damaged, and the supplier to provide the batch of test reports, such as the above phenomenon by the quality inspection department depending on the specific circumstances can be returned.

(4) talcum powder:

Check whether the outer packaging is complete and free of damage, and the supplier to provide the batch of test reports. If there is a bad phenomenon, the quality inspection department can make returns according to the specific situation.

(5) Citric acid, malic acid:

Check whether the outer packaging is complete and free from damage, moisture and lumps. If there are any of the above phenomena, the product will be returned.

(6) Glycerin:

Check whether the outer package is complete and free from damage, and the supplier will provide the testing report of the current batch. If there is any bad phenomenon, the quality inspection department may return the product according to the specific situation.

(7) Phospholipids:

Check whether the outer package is complete and free from damage, and the supplier should provide the testing report of the current batch. If there is any defective phenomenon, the quality inspection department may return the goods according to the specific situation.

(8) Flavor:

Check whether the outer package is complete and free from damage, and the supplier will provide the testing report of the current batch. If there is a bad phenomenon, the quality inspection department can make a return treatment according to the specific situation.

(9) Pigment:

Check whether the outer package is complete and free from damage, and the supplier will provide the testing report of the current batch. If there is a bad phenomenon, the quality inspection department can be returned depending on the specific situation.

(10) wrapping paper acceptance:

Check whether the outer packaging is complete and free of damage, sample check specifications, appearance and hygiene, odor, if there is any non-conformity, the quality control department can be returned depending on the specific circumstances.

(11) carton:

Check whether the outer packaging is complete, and there is no damage, sample checks whether the printing pattern text is clear and consistent with the playing board. If there is a bad phenomenon, the quality control department can make returns according to the specific situation.

💥2. Storage:

According to the warehouse management regulations, the purchased raw materials will be stored in the raw materials warehouse, and control the temperature and humidity. Out of the warehouse should be the principle of first in first out; out of the warehouse with the appropriate amount of processing.

💥3. Crushing and Filtering:

Grind sugar into powdered sugar, and check whether the particle size of powdered sugar meets the relevant process requirements.

💥4. Dosing:

According to the recipe requirements, weigh all kinds of raw and auxiliary materials and additives and set them aside. Double-check the dosing process. Pass the glucose syrup through the sieve before use.

💥5. Gum-based Raw Materials Preparation:

According to the recipe, weigh all materials and set them aside. Double-check the ingredients.

5.1 Kneading:

Kneading is done by a kneading machine according to the process requirements.

5.2 Discharge:

Accurately weighed and packed in stainless steel tray with wax paper pad.

5.3 Gum base storage:

The gum base not used up in time is stored in the warehouse, sealed and marked well, and used within the preservation period.

5.4 Heating:

According to the ratio requirements, receive the glue base for heating.

5.5 Glucose syrup:

Weigh the glucose syrup accurately according to the formula

💥6. Stirring:

According to the recipe, put the weighed glucose syrup, the baked and softened gum base and the corresponding flavor of back-soluble material into the mixer and stir.

💥7. Extrusion:

When the temperature of the extruder reaches the set temperature, add small pieces of stirred sugar to the inlet of the extruder and extrude the material. (Need to control the temperature of the extruder)

💥8. Pressing and Forming:

The extruded material is made into flakes by the forming machine.

💥9. Metal Detection:

(1) products through metal detection before, the sensitivity of the metal detector machine must be adjusted and confirmed

(2) in use, the sensitivity of the metal detector is regularly corrected to prevent failure.

(3) the products rejected by the metal detector machine, reconfirmation, re-over the detector machine was rejected products, must open the package to determine the extent of physical contamination and the source.

💥10. Cooling:

The pressed tablets are cooled naturally by a cold conveyor belt. Cooling time approximately: 20 seconds

💥11. Splicing:

Every 10-15 pieces are stacked neatly

💥12. Aging:

Make a good mark and enter the aging room until the product becomes hard and not deformed.

💥13. Packaging Material Disinfection:

Inner packaging materials are disinfected by a UV lamp for 30 minutes before use.

💥14. Packaging:

Packed by packaging machine.

💥15. Storage:

The warehouse and transportation department protects the products in the storage process according to the requirements of "Warehouse Management Regulations" to ensure that the products are not cross-contaminated, damaged, or spoiled.

💥16. Shipment:

(1) Check the container for deformation and perforation; also check the odor and cleanliness of the container to determine if it is suitable for a food shipment.

(2) Shipment according to regulations to ensure the quality and quantity of the shipment.

Conclusion

Chewing gum goes through quite a process before it ends up in your hands! Next time you enjoy a piece of chewing gum, you'll know just how much work went into making it.

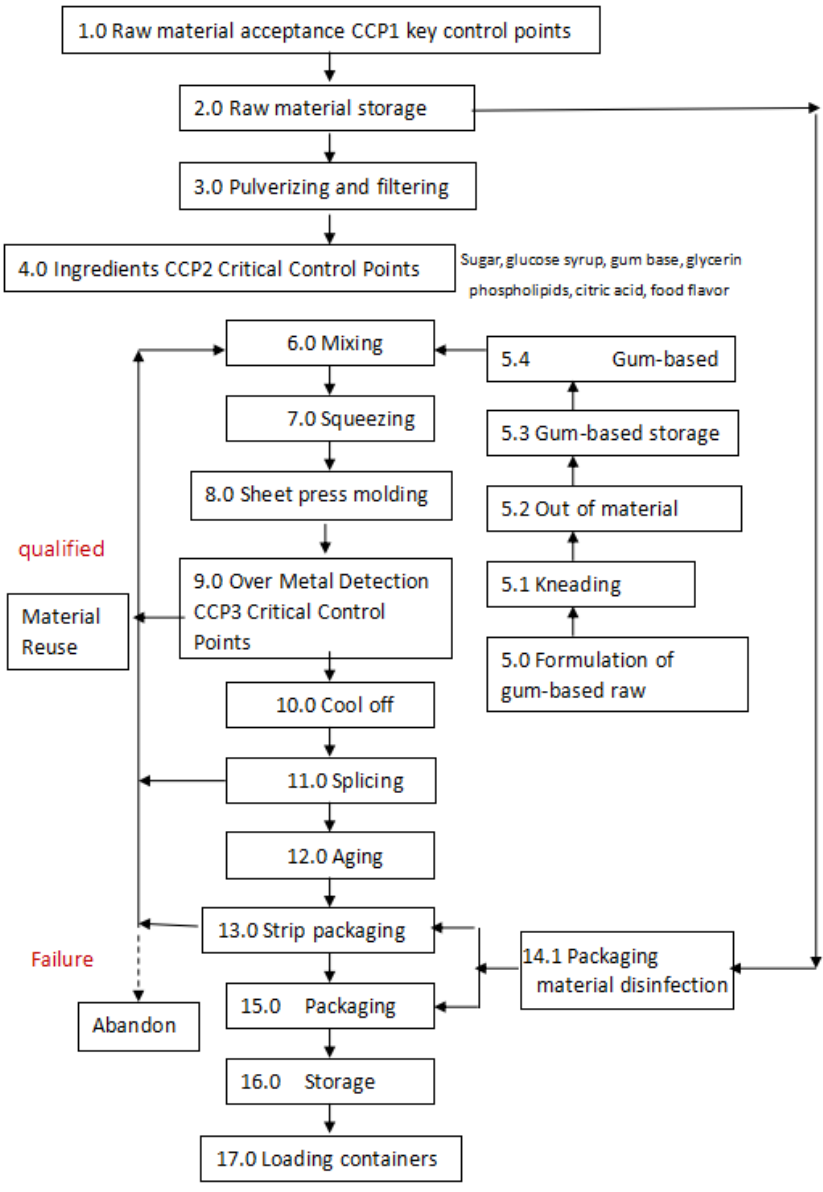

The above is the process of making chewing gum. A flow chart of chewing gum production is attached below. Combined with the text and flow chart, it can help you understand the whole process of chewing gum production more clearly. At the same time, you can also click this link to watch the video of making chewing gum in our factory or check out our other article for more details on chewing gum manufacturing.

Finally, if you have any other questions about the production of chewing gum, please do not hesitate to leave your information in the form at the bottom of the page, and we will have professional technicians to answer your questions. Thanks for reading!

Suifa news

How is Bubble Gum Made in the Factory?

2023-05-24

How Hard Candy is Made in the Factory?

2024-02-28

Get An Instant Quotation

Recommended Products

Bulk Healthy Natural Xylitol Sugar Free Tablet Chewing Gum

Detail

Checking Order

Quality Test Before Delivery

Check Items When Packing

Packaging And Transport

Send Inquiry Now!

Choose Suifa, Boost Your Candy and Gum Project!

Discover excellent gum and candy products at our factory. We create custom solutions for our customers. Join us for exclusive insights, customized products and partnerships. Leave your contact info we'll be back in touch within 12 hours!

Choose Suifa, take your bussiness to the next level!

Contact Us

WELCOME TO SUIFAFOOD YOUR TRUSTED MANUFACTURER OF GUM AND CANDY

Address: No.8 Ritian Road Songxia lndustrial AreaSonggang Nanhai, Foshan, Guangdong, China