How Hard Candy is Made in the Factory?

2024-02-28

How Hard Candy is Made in the Factory?

In the world of candy, hard candies are loved for their unique taste and long-lasting sweetness. But have you ever wondered how these colorful and different shapes of hard candies are born in the factory? Today, let's unravel the mystery of hard candy production and explore every exciting moment from receiving materials to warehousing.

The production of hard candy is actually a delicate art and science. It not only requires precise process control, but also strict quality control. From the selection of raw materials to the release of finished products from the warehouse, each link is crucial, and together they create the outstanding quality of hard candies.

So, are you ready to follow my footsteps and walk into our hard candy factory full of sweetness and mystery?

Ingredients and Equipment

Creating hard candy is a precision task that requires the right ingredients and specialized equipment. The list of ingredients may vary depending on the desired flavor and characteristics of the candy, and the machinery ranges from simple to highly specialized.

Ingredients

At its core, hard candy is made primarily from sugar, corn syrup, and water. The sugar acts as the sweetening agent and lends structure to the candy. Corn syrup helps prevent crystallization, and water is the solvent for the sugar. Additional flavorings, colorants, and acids may be added to create an endless variety of hard candy options.

Equipment

The equipment required in hard candy production is mainly divided into the cooking and forming stages. Cooking equipment includes stainless steel cooking pots, steam kettles, and heat-resistant utensils for stirring. The forming stage utilizes a batch roller, rope sizer, and forming machine, which conditions and shapes the molten candy. Industrial mixers and cookers are also necessary for large-scale production.

Step-by-Step Manufacturing Process

The hard candy overall manufacturing process is as follows:

Receiving the Raw Materials→Sugar Melting→Filtration→Vacuum Boiling→Cooling→Adding Excipients→Blending and molding→Screening and Inner Packaging→Finished Product Inspection→Packaging and warehousing

1. Receiving the Raw Materials

The factory will carefully select high quality raw materials according to the product formula and production plan. These raw materials include sugar, glucose syrup, food coloring, flavoring, etc. Each of these raw materials is strictly inspected and screened by us to ensure that the quality of hard candies is guaranteed from the source.

▲2. Sugar Melting

Next, the raw materials will enter the crucial sugar melting process. In this process, the sugar needs to be completely dissolved under specific temperature and conditions to form a uniform syrup. This step is extremely demanding in terms of temperature and time control, and the slightest mistake may affect the quality and taste of the syrup. For this reason, the factory will adopt advanced equipment and process for sugar dissolution to ensure the quality of the syrup is stable and reliable.

3. Filtration

After the sugar is melted, there may be some tiny impurities or particles in the syrup. In order to ensure the fine and pure taste of hard candies, the factory will carry out meticulous filtration operations to remove these unnecessary ingredients. Through multi-layer filtration and fine treatment, the syrup becomes clearer and more transparent, laying a good foundation for subsequent processes.

▲4. Vacuum Boiling

Immediately after that, the sugar syrup will enter the vacuum boiling process. Under vacuum, the water in the syrup will be rapidly evaporated, while the sugar and other ingredients will undergo a series of complex chemical reactions to produce the unique taste and flavor of hard candy. This process requires precise control of a number of parameters, such as vacuum, temperature and time, to ensure that the consistency and taste of the syrup reaches an ideal state. Vacuum boiling is a key component in the production of hard candies, which gives them their unique hardness and long-lasting sweetness.

5. Cooling

After boiling, the temperature of the syrup is still very high and needs to be cooled down rapidly to fix its form. The factory will use advanced cooling equipment and technology, such as cold air circulation, water cooling, etc., to ensure that the syrup is rapidly cooled down to a suitable temperature in a short period of time. This not only prevents the syrup from deteriorating due to overheating, but also gives the hard candy a crispier texture.

▲6. Adding Excipients

Adding carefully selected excipients to the cooled syrup is a key step in adding flavor and color to hard candies. The addition of flavors, colors and other excipients not only gives hard candies a colorful appearance, but also adds a unique taste and aroma. These ingredients must be food safe and meet regulatory standards. The factory will carefully mix the types and proportions of excipients according to the product demand and consumer preferences to create hard candy products with different characteristics.

7. Blending and molding

After adding the excipients, the syrup needs to be fully blended to ensure that the various ingredients are evenly distributed. The blended syrup is then fed into the molding equipment, where it is extruded and cut through the molds to create attractive shapes. This process requires great skill and experience to ensure that each piece of hard candy takes on a perfect form.

8. Screening and Inner Packaging

After molding, hard candies will go through a strict screening process to eliminate products that do not meet the standards. During the screening process, the staff will scrutinize the appearance, taste and weight of the hard candies to make sure that only high quality hard candies will be sent to the next stage of the process. The screened hard candies will be carefully packed in exquisite inner bags to protect them from contamination and damage.

9. Finished Product Inspection

Before the hard candies leave the factory, there is one last important process - finished product inspection. This is the last comprehensive check on the quality of hard candies to ensure that every hard candy meets the factory's high quality standards. The inspection includes taste, appearance, packaging and other aspects, and only those hard candies that pass the strict inspection will be qualified to leave the factory.

10. Packaging and Warehousing

Finally, the hard candies will be sent to the warehouse after being beautifully packaged, waiting to be shipped to all over the world. The packaging not only protects the product, but also enhances the product's class and attractiveness. According to the market demand and consumers' preference, the factory will design a variety of exquisite packaging solutions, so that the hard candy will show the best image in front of the consumers. Meanwhile, the warehouse management will carefully arrange the storage and transportation of the goods to ensure that the hard candies can maintain excellent quality throughout the process.

Emphasizing the Significance of Temperature Control

Temperature control is paramount throughout the candy-making process, influencing factors such as texture, flavor, and shelf life. Precise monitoring and adjustment of temperatures ensure consistency and uniformity in the final product.

Ensuring Quality Every Step of the Way

Throughout the production process, quality control is paramount. From receiving ingredients to warehousing the finished product, a rigorous testing and inspection regime must be in place. Batch testing, visual inspection, and taste testing are all part of the process to ensure each candy meets the company's quality standards.

FAQ

Q: What are the main ingredients used in making hard candy?

A: The main ingredients used in making hard candy are sugar, water, flavorings, and colorants.

Q: How is sugar dissolved to create the candy syrup?

A: Sugar is dissolved in water to create the candy syrup by heating the mixture until the sugar crystals completely dissolve, forming a clear syrup.

Q: Why is vacuum boiling used in the candy-making process?

A: Vacuum boiling is used in the candy-making process to lower the boiling point of the syrup, preventing caramelization and allowing for precise temperature control, resulting in a smooth and consistent texture.

Q: What role do auxiliary ingredients play in hard candy production?

A: Auxiliary ingredients such as flavorings and colorants add flavor and color to the hard candy, enhancing its taste and appearance.

Q: How are flavors and colors added to the candy syrup?

A: Flavors and colors are added to the candy syrup during the cooling stage after the sugar has been dissolved, allowing the ingredients to blend evenly into the mixture.

Q: What is the significance of temperature control during candy production?

A: Temperature control is crucial during candy production to ensure proper crystallization, texture, and shelf stability of the final product.

Q: How are hard candy molds created and utilized?

A: Hard candy molds are created using heat-resistant materials such as silicone or metal. The candy syrup is poured into these molds to shape the candies into various designs before they cool and harden.

Q: What quality control procedures are in place to ensure the integrity of the candies?

A: Stringent quality control procedures, including visual inspection, taste testing, and measurement of dimensions and weight, are implemented throughout the production process to ensure the integrity and consistency of the candies.

Q: How are hard candies packaged to maintain freshness?

A: Hard candies are delicately packaged in airtight containers or wrappers to maintain their freshness and prevent moisture absorption, preserving their quality and flavor.

Q: What steps are taken to ensure uniformity and consistency in the final product?

A: Steps such as blending, molding, and screening are taken to ensure uniform distribution of ingredients and consistent shaping of the candies, resulting in a high-quality final product.

Conclusion

In conclusion, the production of hard candy is a harmonious blend of artistry, precision, and science. From the choice of ingredients and equipment to the detailed production process, every aspect plays a crucial role in creating high-quality, safe, and delicious hard candy. By following this guide, manufacturers can master the art of hard candy production, ensuring their sweet creations are enjoyed by countless customers.

Suifa news

How is Bubble Gum Made in the Factory?

2023-05-24

How Hard Candy is Made in the Factory?

2024-02-28

Get An Instant Quotation

Recommended Products

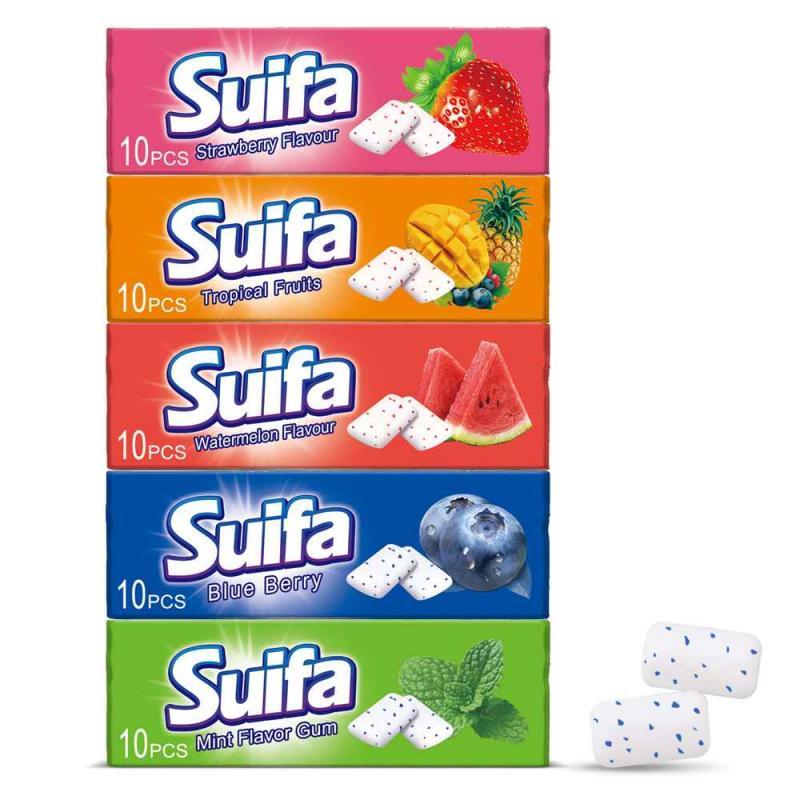

Bulk Healthy Natural Xylitol Sugar Free Tablet Chewing Gum

Detail

Checking Order

Quality Test Before Delivery

Check Items When Packing

Packaging And Transport

Send Inquiry Now!

Choose Suifa, Boost Your Candy and Gum Project!

Discover excellent gum and candy products at our factory. We create custom solutions for our customers. Join us for exclusive insights, customized products and partnerships. Leave your contact info we'll be back in touch within 12 hours!

Choose Suifa, take your bussiness to the next level!

Contact Us

WELCOME TO SUIFAFOOD YOUR TRUSTED MANUFACTURER OF GUM AND CANDY

Address: No.8 Ritian Road Songxia lndustrial AreaSonggang Nanhai, Foshan, Guangdong, China