How is Bubble Gum Made in the Factory?

2023-05-24

How is Bubble Gum Made in the Factory?

|Bubble Gum Making Process

Bubble gum is a popular candy among kids and adults alike. With its sweet and fruity taste, it's hard to resist this chewy goodness. But have you ever wondered how this popular candy is made? In this blog post, we'll take you through the step-by-step process of making bubble gum in a factory.

Step 1: Mixing the Ingredients

The first step in making bubble gum is to mix the ingredients. The main ingredients used in bubble gum manufacturing include sugar, corn syrup, and gum base. The gum base is the main ingredient that gives the gum its chewy texture. Once the ingredients are mixed, they are heated and stirred until they form a thick syrup-like consistency.

Step 2: Adding Flavor and Color

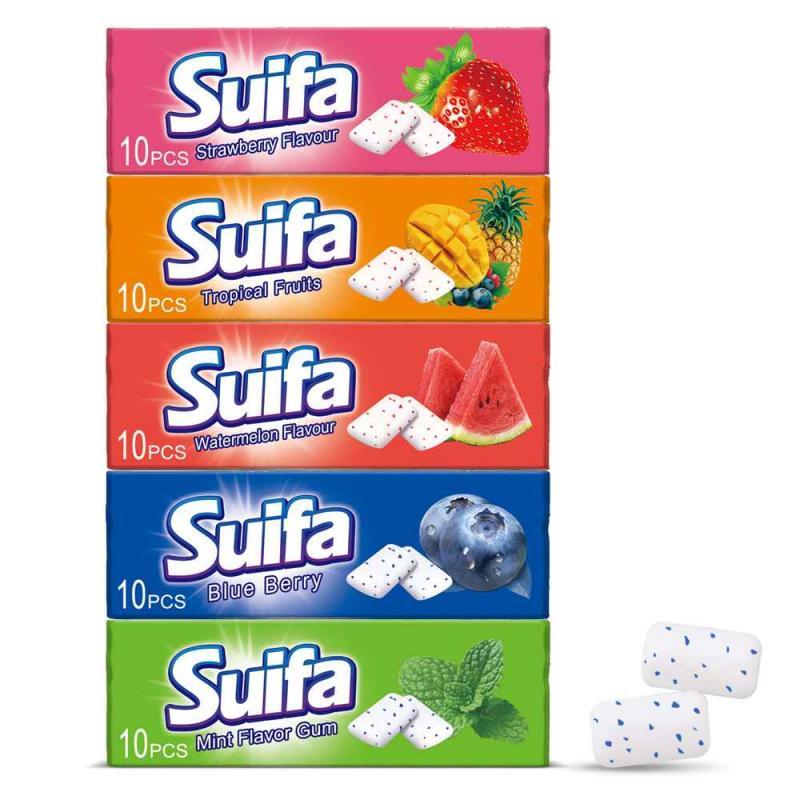

Once the mixture has reached the desired consistency, it is time to add the flavor and color. There are a wide variety of flavors and colors used in bubble gum, such as strawberry, grape, and watermelon. The flavor and color are added to the mixture and stirred thoroughly until it is evenly distributed and the desired flavor and color are achieved.

Step 3: Heating

Once the ingredients are mixed, the mixture is heated in a cooking pot to a temperature of around 325°F (163°C). This helps to melt the ingredients and create a homogenous mixture.

Step 4: Rolling and Shaping the Gum

When the temperature of the extruder reaches the set temperature, the gum is fed into an extruder, which shapes the gum into long strips. The long strips of gum are then cut into spheres or other shapes using a cutter.

Step 5: Cooling

Once the gum has been shaped and dusted, it is cooled to harden and hold it in place. This process takes place in a special cooling channel that allows the gum to cool evenly. The cooling time is approximately 60 seconds.

Step 6: Selection and Conditioning

After the bubble gum is formed, workers will pick out the ones that are not in good shape. The formed bubble gum will be aged in the aging- room until the product becomes hard and not deformed. Then the gum will be placed in the warm air to make it easier to chew.

Step 7: Coating

The coloring is dissolved and poured into the coating machine. Through the rapid operation of the coating machine, the gum is coated with a thin layer of sugar and other colored coatings that give it a bright appearance and add more flavor.

Step 8: Polishing

After the bubble gum is coated, add edible polish to polish the surface of the gum to make it more shiny.

Step 9: Quality Control

Before being packaged, the bubble gum undergoes a series of quality control checks. Weight, size, flavor, and color consistency are all checked to ensure that each piece of gum is of the highest quality.

Step 10: Packing and Crating

Packing in different specifications according to the customer's requirements. Check the container for deformation and perforation before loading; check the container to determine if it is suitable for a food shipment.

Conclusion

Bubble gum production is a complex process that involves several steps. Each step must be carefully controlled to ensure that the final product is of high quality and meets customer expectations.

FAQ

Bubble gum typically contains the following ingredients:

1. Gum base: This is the main ingredient in bubble gum, which gives it its chewy texture. Gum base is typically made from a blend of natural and synthetic materials like elastomers, resins, and waxes.

2. Sugar: Bubble gum is sweetened with sugar, which provides the gum with its distinctive taste.

3. Corn syrup: Corn syrup is used as a binding agent and to help keep the gum moist.

4. Flavorings: Bubble gum can be flavored with a variety of natural and synthetic flavors, such as fruit, mint, and cinnamon.

5. Softeners: Bubble gum also contains softeners such as glycerin and vegetable oil, which help to keep the gum soft and pliable.

6. Coloring agents: To give the gum its bright colors, coloring agents are added to the mixture.

Several machines are used to make bubble gum.

Here are some of the key machines involved in the production process:

1. Mixing machine: A large mixing machine is used to blend together the gum base, sugar, corn syrup, and flavorings.

2. Cooking pot: The mixed ingredients are then heated in a cooking pot to melt the ingredients and create a homogenous mixture.

3. Extruder: Once the mixture has cooled down, it is fed into an extruder machine that shapes the gum into long strips.

4. Cutting machine: The long strips of gum are then cut into smaller, bite-sized pieces by a cutting machine.

5. Conditioning room: The cut pieces of gum are then conditioned in a warm room to soften them and make them more pliable.

6. Coating machine: After conditioning, the gum is coated with a thin layer of sugar or other coatings to give it a glossy appearance and add more flavor. This is done using a coating machine.

7. Packaging machine: Once the gum has been coated, it is ready for packaging. The gum is typically packaged in individual pieces or sticks and wrapped in foil or paper. A packaging machine is used to pack and wrap the gum.

8. Quality control machines: Throughout the entire production process, quality control machines are used to ensure that the gum is of high quality and meets the company's standards for taste, texture, and consistency.

These machines are designed to handle large volumes of gum production and help to automate the production process, making it more efficient and cost-effective.

Suifa news

How is Bubble Gum Made in the Factory?

2023-05-24

How Hard Candy is Made in the Factory?

2024-02-28

Get An Instant Quotation

Recommended Products

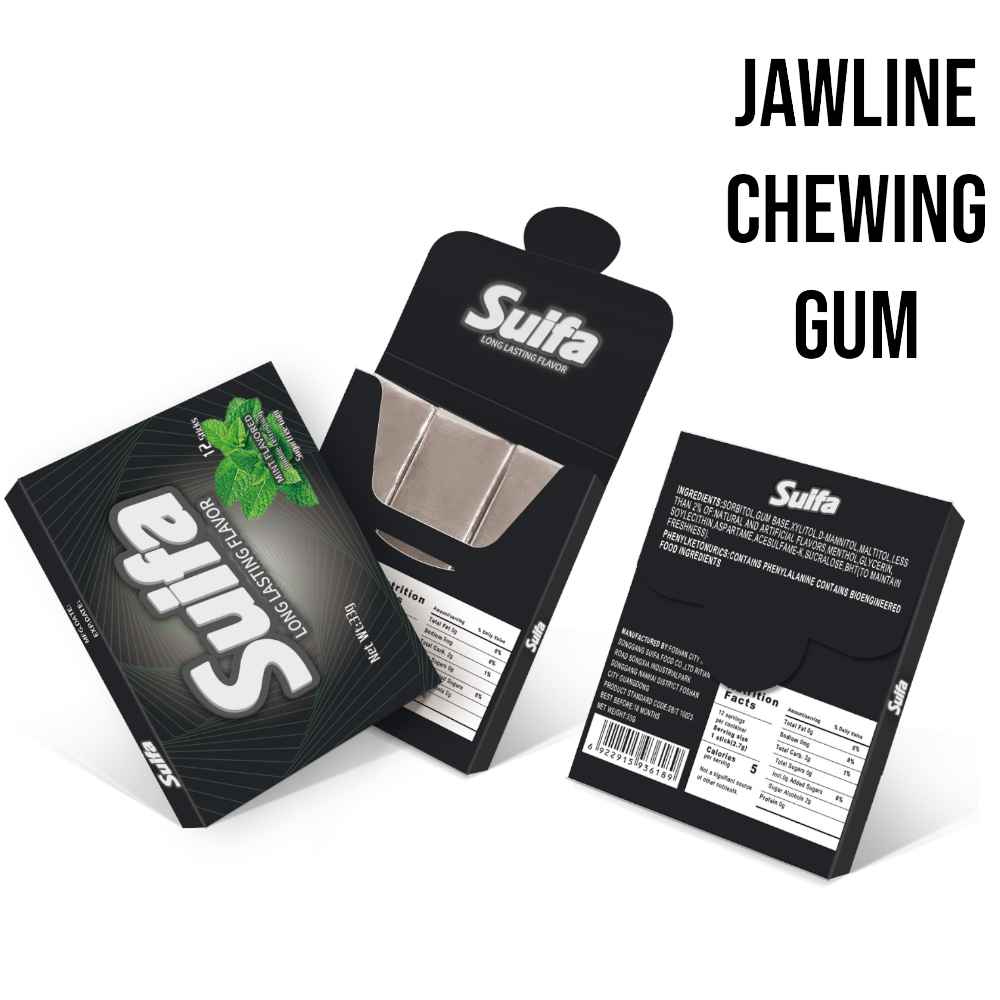

Bulk Healthy Natural Xylitol Sugar Free Tablet Chewing Gum

Detail

Checking Order

Quality Test Before Delivery

Check Items When Packing

Packaging And Transport

Send Inquiry Now!

Choose Suifa, Boost Your Candy and Gum Project!

Discover excellent gum and candy products at our factory. We create custom solutions for our customers. Join us for exclusive insights, customized products and partnerships. Leave your contact info we'll be back in touch within 12 hours!

Choose Suifa, take your bussiness to the next level!

Contact Us

WELCOME TO SUIFAFOOD YOUR TRUSTED MANUFACTURER OF GUM AND CANDY

Address: No.8 Ritian Road Songxia lndustrial AreaSonggang Nanhai, Foshan, Guangdong, China